Views: 0 Author: Site Editor Publish Time: 2025-10-30 Origin: Site

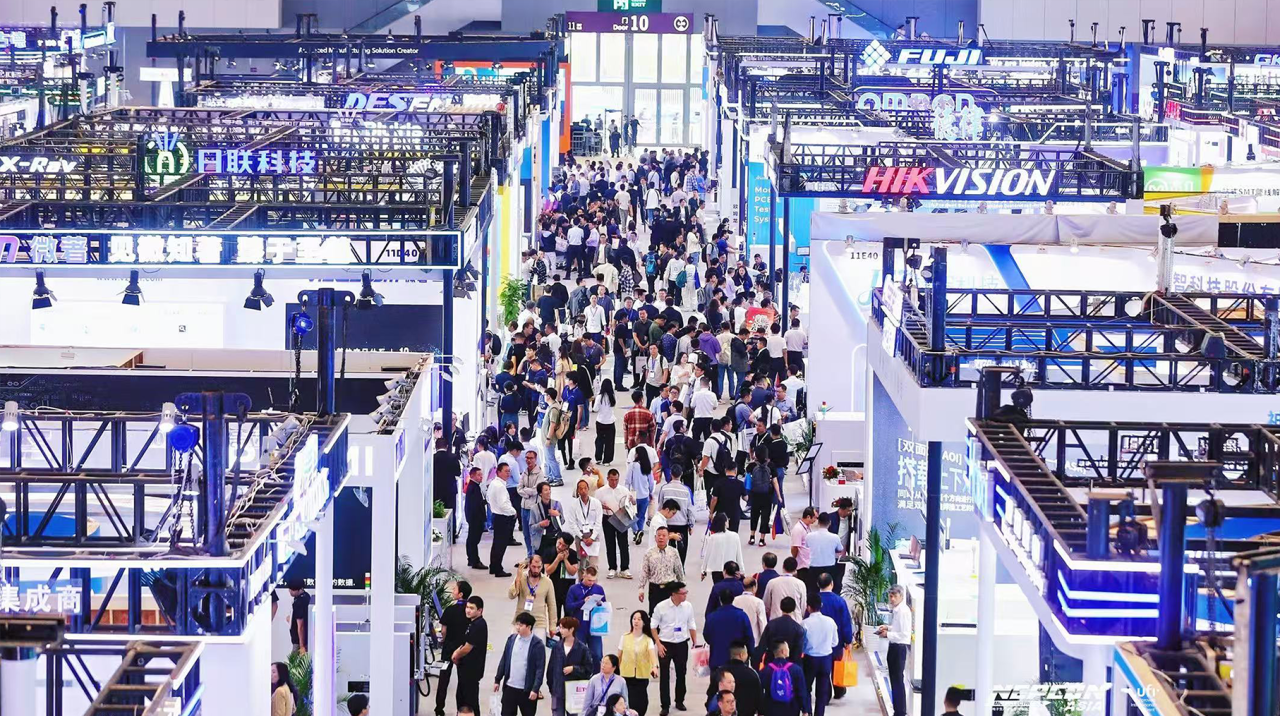

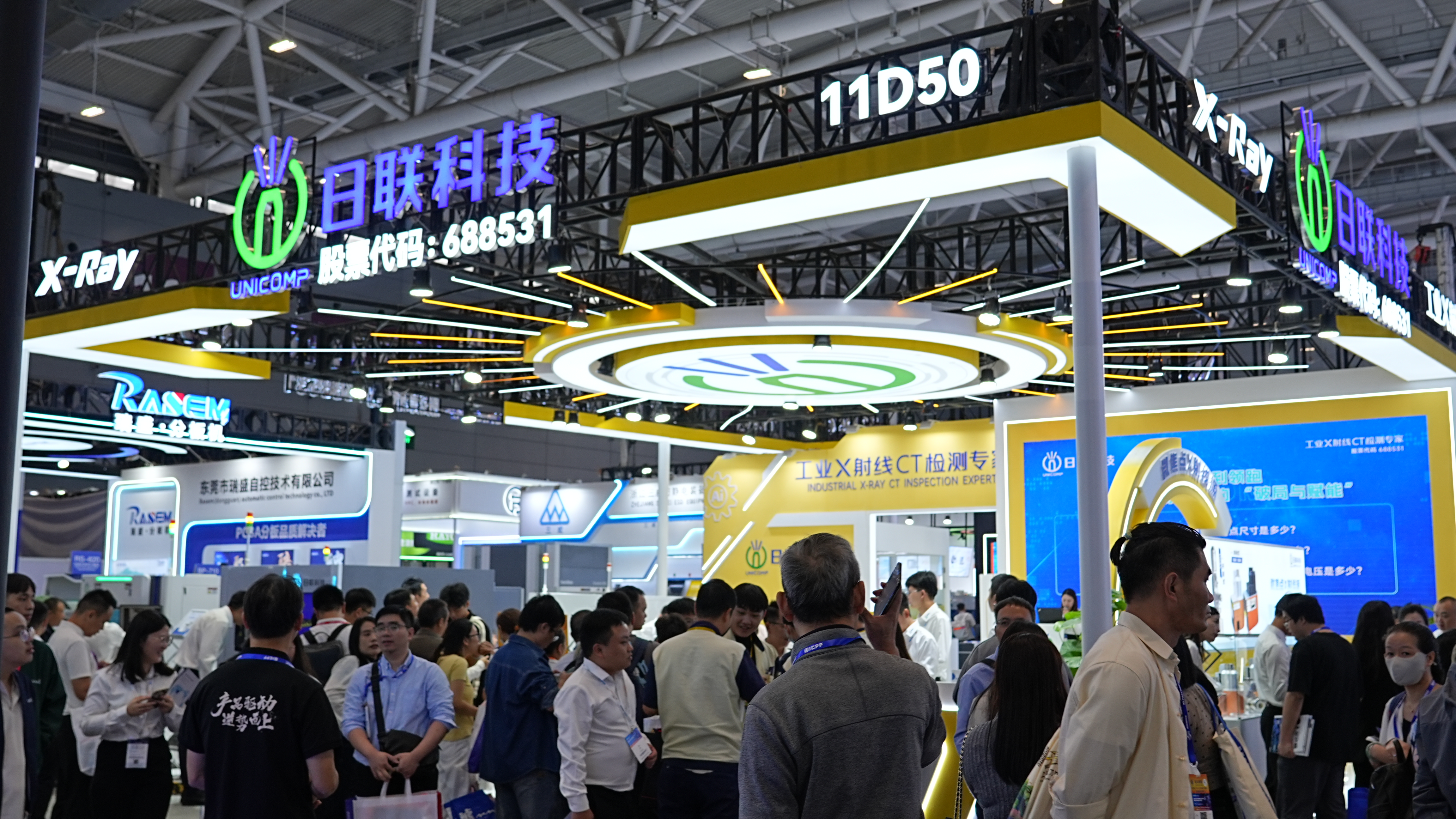

The NEPCON ASIA 2025 exhibition has officially opened under the theme “Smart Electronic Ecosystem • Global Cross-Border Opportunities.”

This year’s event brings together cutting-edge technologies across AI, semiconductors, and low-altitude flight, showcasing the latest innovations in electronic manufacturing — enabling a one-stop, comprehensive experience for industry professionals.

At Hall 11, Booth D50, Unicomp Technology Group presents its breakthrough “AI + X-ray Intelligent Inspection” solutions, featuring high-precision inspection systems and self-developed X-ray sources that directly address key challenges in the semiconductor and electronics sectors — empowering customers towards smarter manufacturing.

Unicomp Launches China’s First 160kV Nano-Scale Open-Type X-ray Source!

Through thousands of experiments and process iterations, Unicomp’s R&D team achieved a major domestic breakthrough — the first open-type X-ray source developed entirely in China.

Designed for the semiconductor industry, it delivers:

· Ultra-high resolution: 0.8 μm

· High penetration: up to 160kV tube voltage

· Digital intelligent control: for stable, efficient operation

This innovation tackles the most demanding inspection needs in wafer, advanced packaging, and multi-layer stacked chips, setting a new benchmark for nano-level precision.

Facing Semiconductor Complexity — How Does Unicomp Solve It?

01 ▪ Nano-Level Defect Detection

AX9500 | 3D/CT Open-Type Nano Inspection

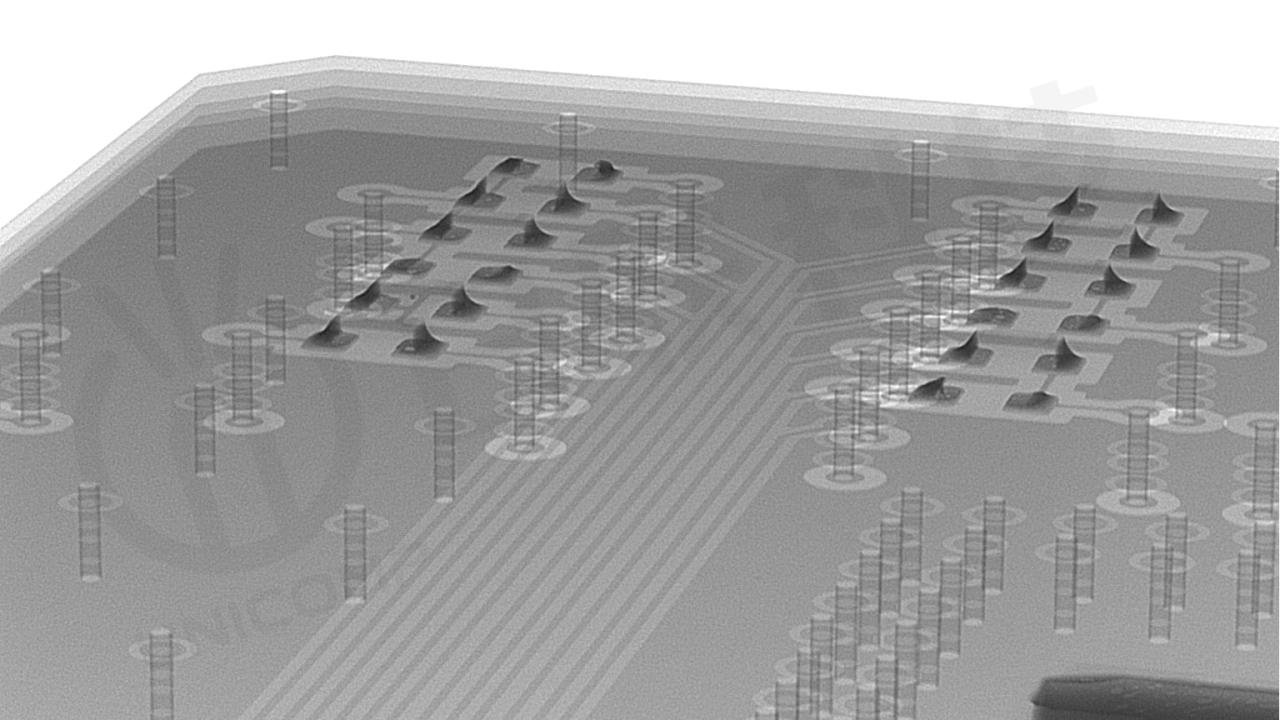

2000X magnification and multi-mode imaging precisely capture defects such as wafer bump bridging, cold soldering, and MEMS voids, powered by Unicomp’s AI-driven large model for intelligent identification.

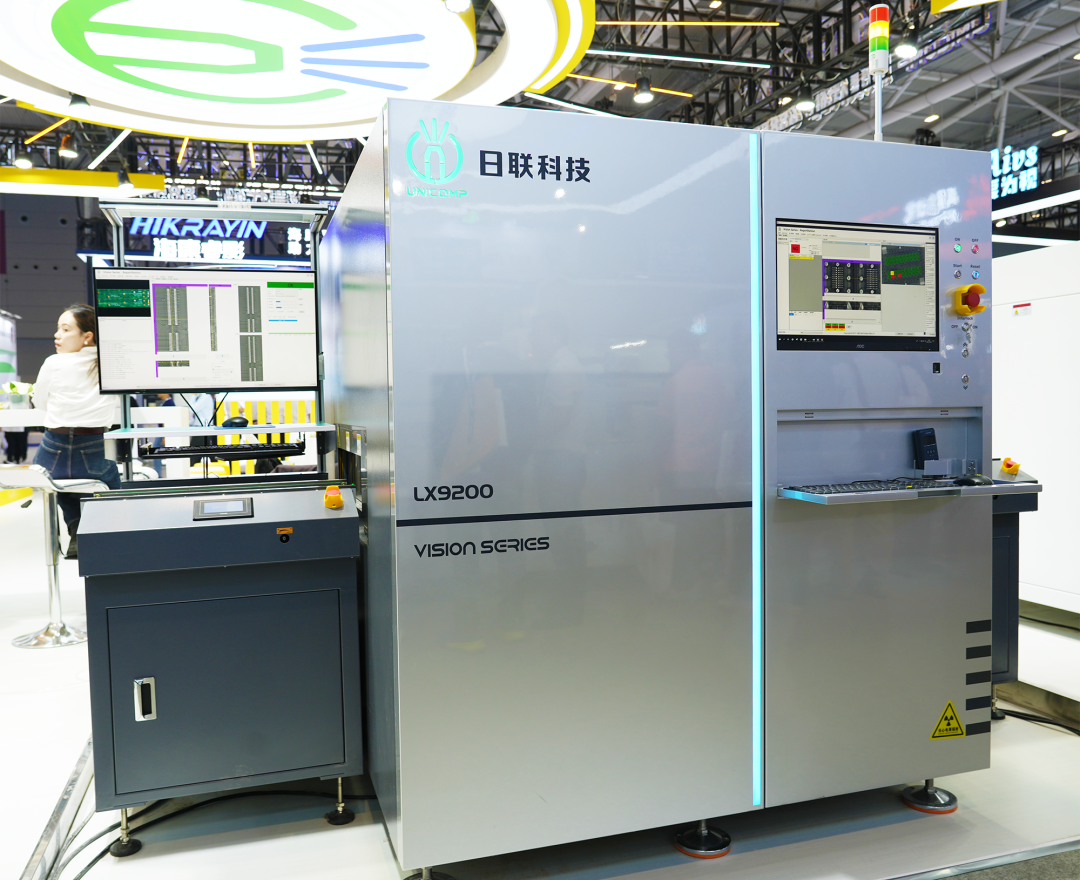

02 ▪ End-to-End Quality Control on Semiconductor/Electronics Lines

LX9200 AXI | 3D/CT In-line High-Density Module Inspection

Equipped with a self-developed micro-focus X-ray source, it penetrates 280mm aluminum alloy or cast iron housings, achieving 360° AI-based positioning for accurate, automated defect detection.

LX2000 Series | High-Precision In-line X-ray Inspection

High-resolution real-time imaging captures micron-level voids and micro-cracks in solder joints, supported by nine integrated AI algorithms for high-speed full inspection.

03 ▪ Zero-Blindspot Quality Control for Compact, High-Density Products

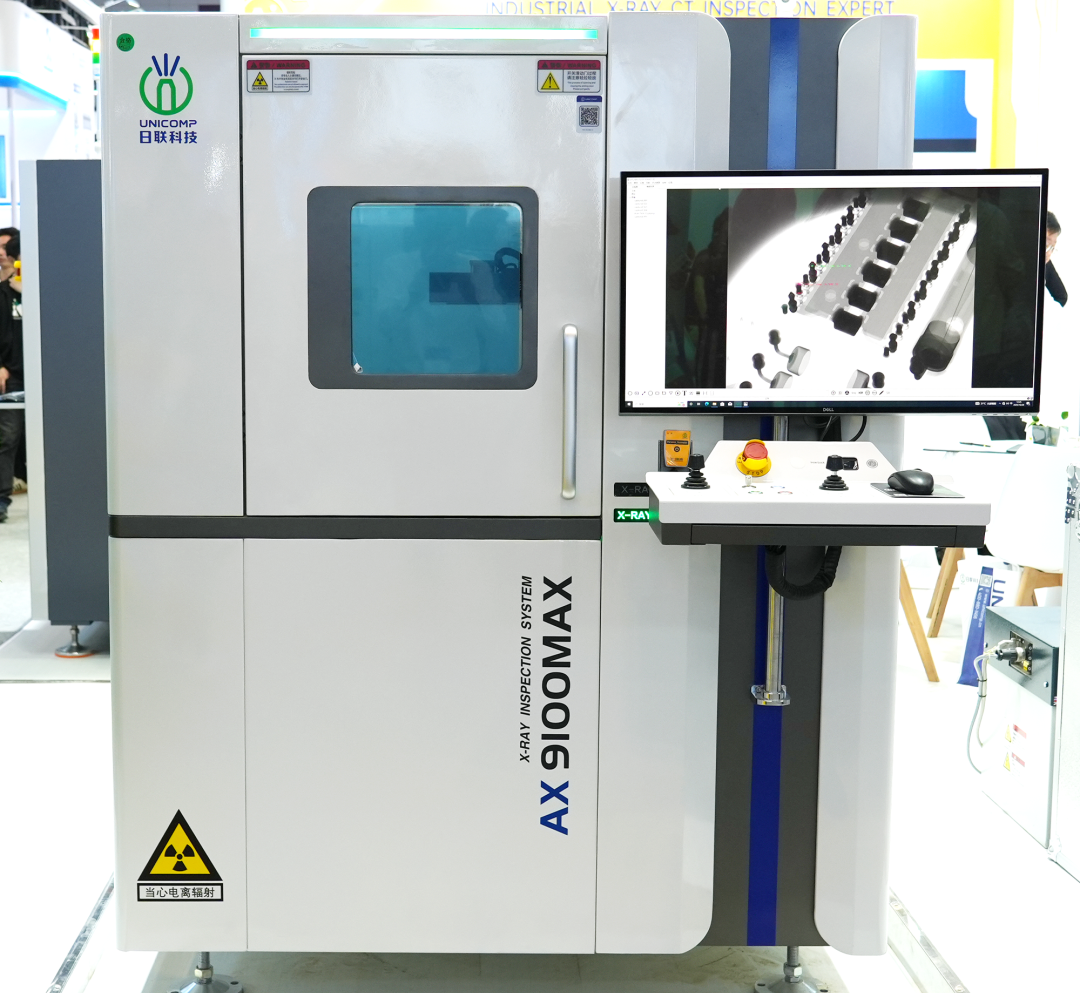

AX9100MAX | AI Precision X-ray Inspection System

Designed for thick, dense, and large electronic/semiconductor assemblies, it integrates AI-based super-resolution imaging, HD navigation, and dynamic tracking to precisely detect and monitor voids, misalignment, and solder height issues.

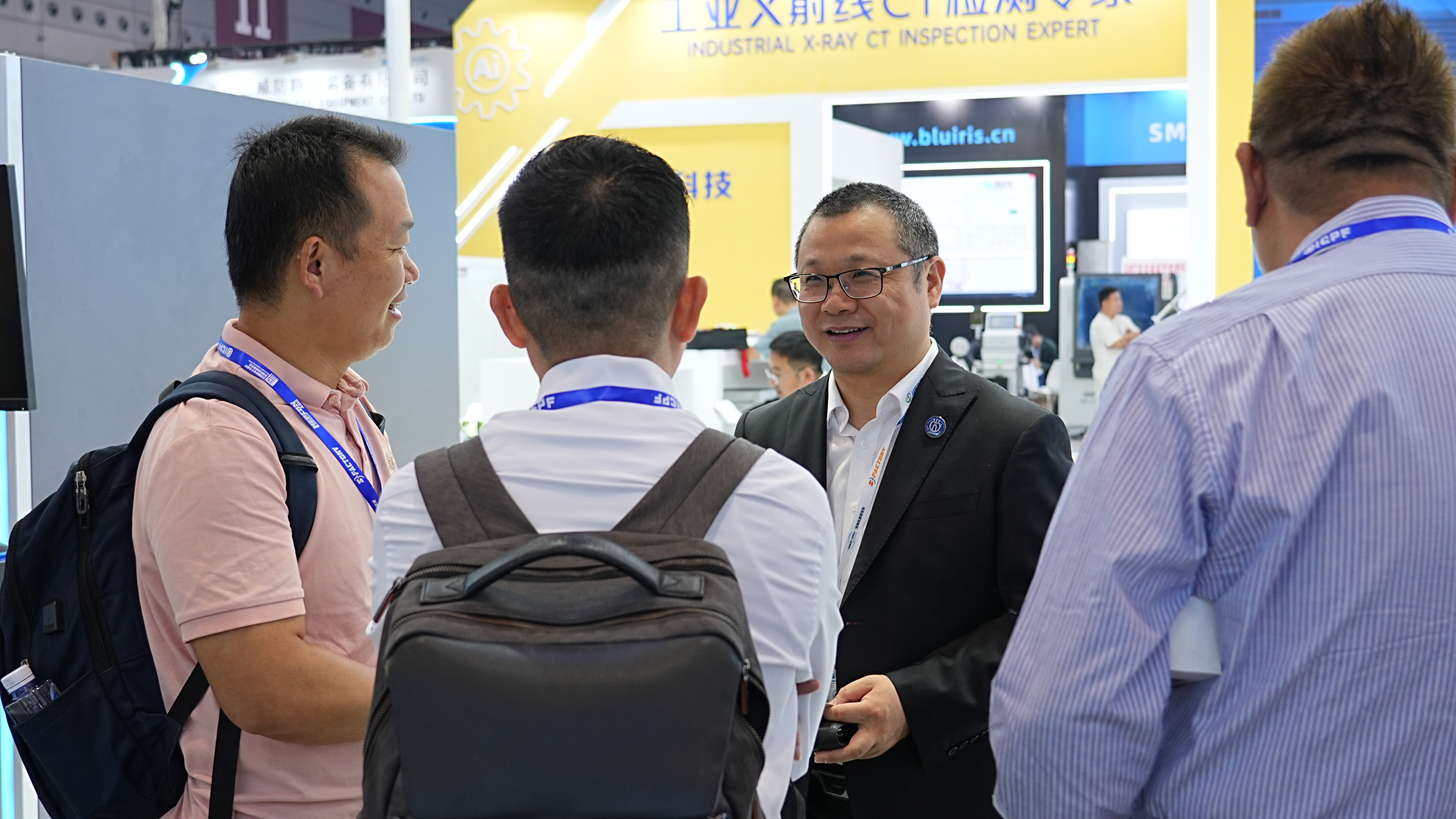

Technology Exchange Highlights

At the exhibition, Unicomp experts hosted multiple technical sharing sessions, engaging visitors in in-depth discussions on how AI + X-ray technologies are redefining semiconductor and electronics quality assurance.

Looking Ahead

Unicomp will continue advancing its AI + X-ray intelligent inspection closed-loop, driving comprehensive quality control and enabling the semiconductor and electronics industries to achieve higher yield and productivity — simultaneously.