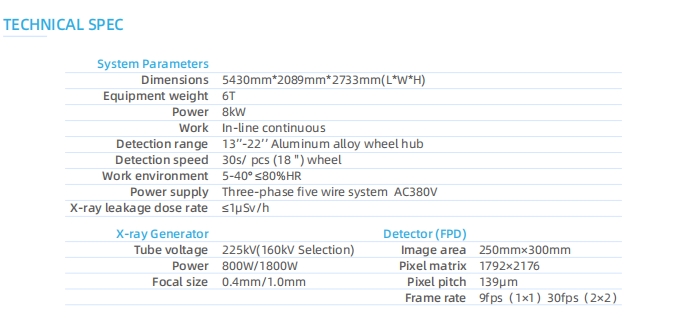

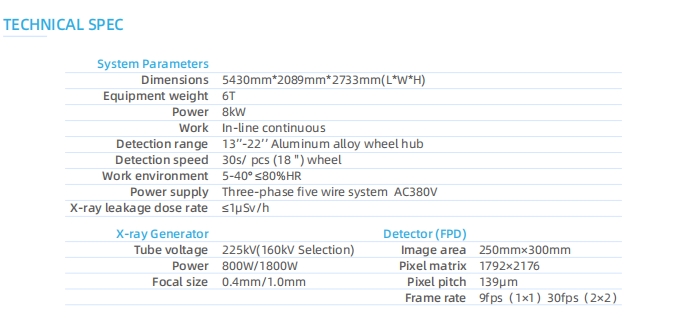

| Availability: | |

|---|---|

UNI-160-Y2-D9

UNICOMP

Software Function:

Image processing: brightness and contrast adjustment; stacking frames, window width and level adjustment; image enhancement, filtering, sharpening, invert, relief and bubble measure;ove, zoom in, zoom out, display image scaling, display the current mouse coordinates and gray values Image measurement: distance, radius, polygon, angle measurement; arrows and text labels; save the image after processing;

Motion control: the speed adjustment of each moving axis; CNC programming; manual operation; Automatic identification of the wheel hub, automatic calculation of the bubble;

Additional function :

● Wheel clamping synchronous drive to make sure the precise control.

● Intelligent algorithm with X-Ray source and the flat panel walking swing angle.

● New wheel hub test has teaching function, manual setting, automatic save functions

● Automatic wheel hub and software self matching.

● Mechanical modular design and compatible with 160KV/225KV x-ray source with 9 inch tablet intensifier and installation.

● Automatic calculate the bubble of the wheel hub, set aside the output interface of the automatic sorting.

● Set aside industrial cloud interface, data and pictures in real time upload, with traceability and large data analysis function (optional).

Applications:

● 13”- 22”Size Wheel Hub Inspection

● 14”- 26”Size Wheel Hub Inspection

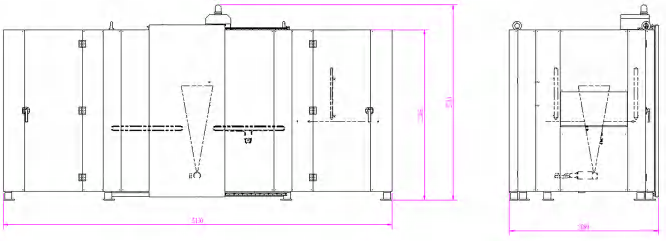

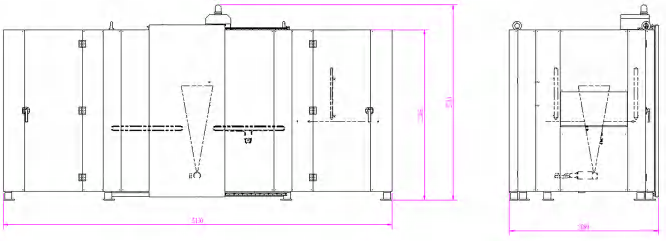

MACHINE FOOTPRINT:

Inspection Images:

Software Function:

Image processing: brightness and contrast adjustment; stacking frames, window width and level adjustment; image enhancement, filtering, sharpening, invert, relief and bubble measure;ove, zoom in, zoom out, display image scaling, display the current mouse coordinates and gray values Image measurement: distance, radius, polygon, angle measurement; arrows and text labels; save the image after processing;

Motion control: the speed adjustment of each moving axis; CNC programming; manual operation; Automatic identification of the wheel hub, automatic calculation of the bubble;

Additional function :

● Wheel clamping synchronous drive to make sure the precise control.

● Intelligent algorithm with X-Ray source and the flat panel walking swing angle.

● New wheel hub test has teaching function, manual setting, automatic save functions

● Automatic wheel hub and software self matching.

● Mechanical modular design and compatible with 160KV/225KV x-ray source with 9 inch tablet intensifier and installation.

● Automatic calculate the bubble of the wheel hub, set aside the output interface of the automatic sorting.

● Set aside industrial cloud interface, data and pictures in real time upload, with traceability and large data analysis function (optional).

Applications:

● 13”- 22”Size Wheel Hub Inspection

● 14”- 26”Size Wheel Hub Inspection

MACHINE FOOTPRINT:

Inspection Images: